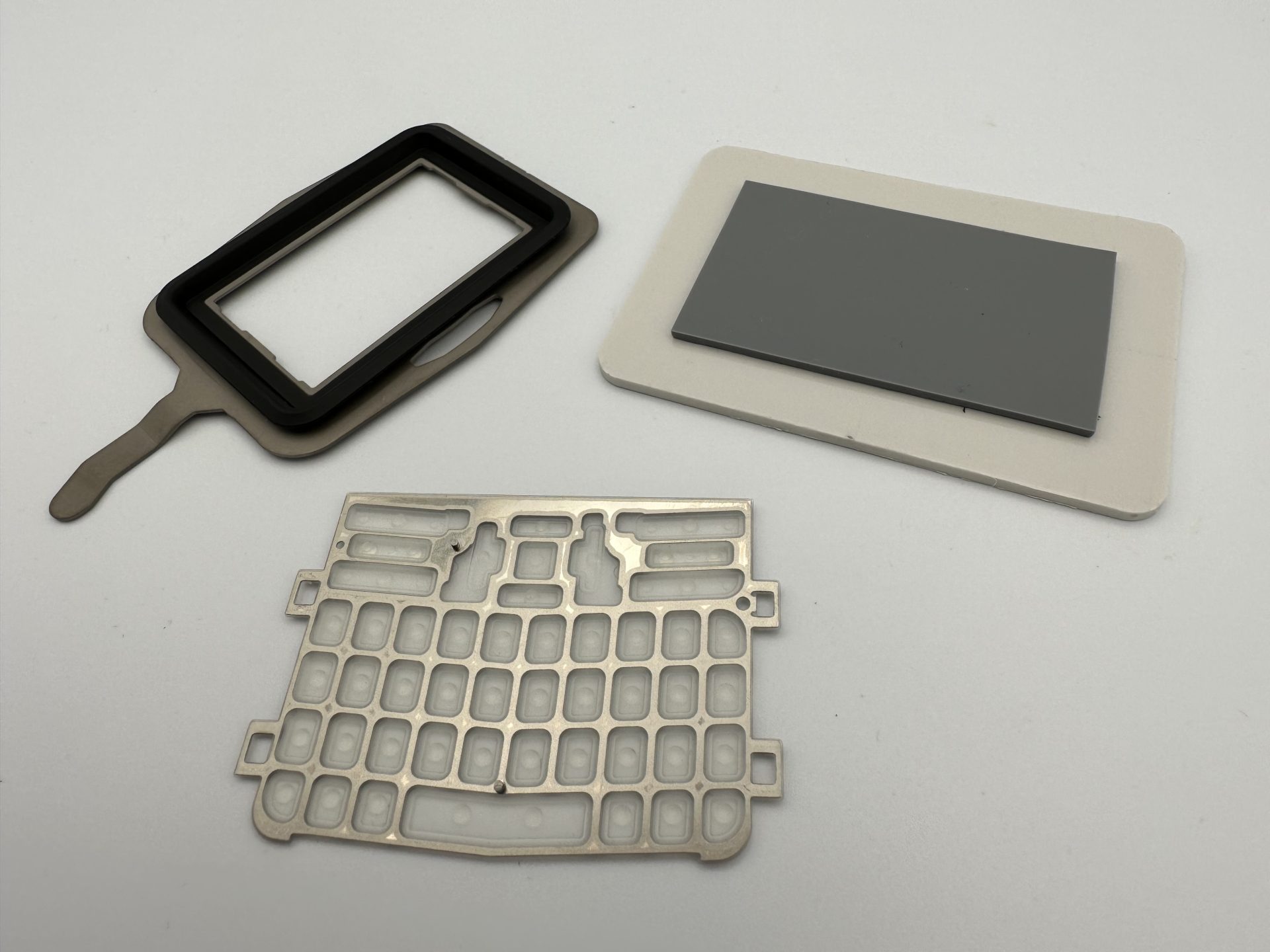

In the past, Sunarrow manufactured cell phone key sheets as its main product.

The integrated production system we developed there continues to be the basis for manufacturing a variety of products today.

An integrated production system is a system in which all processes are handled by one company when manufacturing a product.

At Sunarrow, this is the basic manufacturing process for silicone rubber and resin products. Design - molding - decoration - quality controlYou can do the whole process in-house.

Furthermore, we also have applied technologies such as adhesive and bonding technologies for different materials such as resin and rubber, and film processing.

Therefore, even for special specifications, we may be able to handle integrated production, and this can be said to be a feature of Sunarrow's integrated production system.

If orders are placed with multiple companies for each manufacturing process, there is a concern that communication costs and labor will be incurred for each company.

However, at Sunarrow, we are responsible for all such processes, so we are able to simplify procurement operations.

In addition, you can expect flexible delivery adjustments and cost reductions that are possible because of the integrated production that does not involve other companies.

design

Sunarrow designs all products, molds, jigs and tools in-house.

This leads to a stable supply of products, short delivery times, and cost reductions.

Utilizing the knowledge we have cultivated from our long experience as a manufacturing company,

Our strength is our detailed design that takes into consideration the post-production process.

We also have analysis equipment for design, so

Experience as a manufacturing company × Utilization of analysis equipment

This allows us to proactively resolve design issues that may occur during the production process.

In addition to general molding technologies such as resin, rubber, and UV molding,

Encapsulating electronic components such as substrates with silicone

"Electronic parts silicone encapsulation"

It is attractive to be able to realize high durability and design.

“Covered silicone”

We also have our own unique molding technology.

Molding

Decoration

In terms of decoration technology that changes the appearance and texture of molded products,

Vapor deposition, painting, printing, laser processingsuch as

We have various technologies.

Above all, the ultra-thin seat has a three-dimensional logo and letters.

Composite technology (3D texture)teeth

This is Sunarrow's unique technology that was jointly patented.

We have received interest from customers in various fields.

When a quality defect occurs, we promptly analyze the cause and

Customer feedback is essential, but

We also have an after-sales follow-up system in place.

variousIn-house equipment for evaluation and analysisBecause of this,

We are able to quickly handle various environmental tests and reliability tests in-house.

This is why we continue to be trusted by our customers.

quality management

Bonding

By establishing adhesive technology between silicone rubber and resin, we

A world patent was obtained in 1992.

in recent yearssilicone rubber + resinNot only,

We also have a track record of adhesion and bonding with metal, glass, and substrates.

In addition to similar materials such as resin x resin,

It can also handle bonding and adhesion of a wide variety of materials.

This is a strength unique to Sun Arrow.