Resin molding

・Used common molding equipment at all locations within the group.

・After design and initial prototyping in Japan, production can be carried out by transferring the mold along with molding condition data to an overseas factory.

・We also develop our own proprietary technology derived from existing technology.

injection molding

Resin molding (plastic injection molding) is a molding method that uses an injection molding machine and a mold.thermoplastic resin materialis heated and melted, fed into a mold, and then cooled to form the desired shape. It is called "injection molding" because it resembles how liquid is sent with a syringe. Even complex shapes can be molded by making full use of mold technology, so it can be said that it is a technology that can meet various needs.

*Thermoplastic resin is a plastic that softens when heated and hardens when cooled to a certain temperature.

Even once hardened, it can be softened many times when heated, making it a suitable material for recycling and used in a wide range of products.

Also, the method of integrally molding two different resins into onetwo-color moldingcalled. At our company, we can mold various resin materials with 100t class molding machines as our main force, and we can also handle two-color molding, so we can pursue design that cannot be reproduced with single-color molding, You can also expect cost reduction by reduction.

A suitable mold is required for stable production and injection molding of complex shapes. We handle a wide range of mold design and mold processing, so please feel free to leave it to us.

| merit | Demerit |

| Can mass produce products of the same quality | The initial cost of molds, etc. may be high. |

| Even complex shapes can be manufactured | In the case of two-color molding, the compatibility of the material combination is important. |

| In the case of two-color molding, the lead time for assembly and adhesion, etc. and cycle costs can be expected to be reduced |

Resin insert molding

Insert molding is a molding method that integrally molds parts such as metal that you want to integrate with plastic resin.

In addition to metal parts, it is also possible to integrate different types of resin. After insert parts are set in the mold, melted plastic resin is poured into them to integrate them. Same as two-color moldingThe key point is that it can be expected to reduce assembly and gluing processes.is. On the other hand, advanced mold design technology and know-how are required. We also develop unique technologies that utilize our experience and know-how in manufacturing various insert molded products.

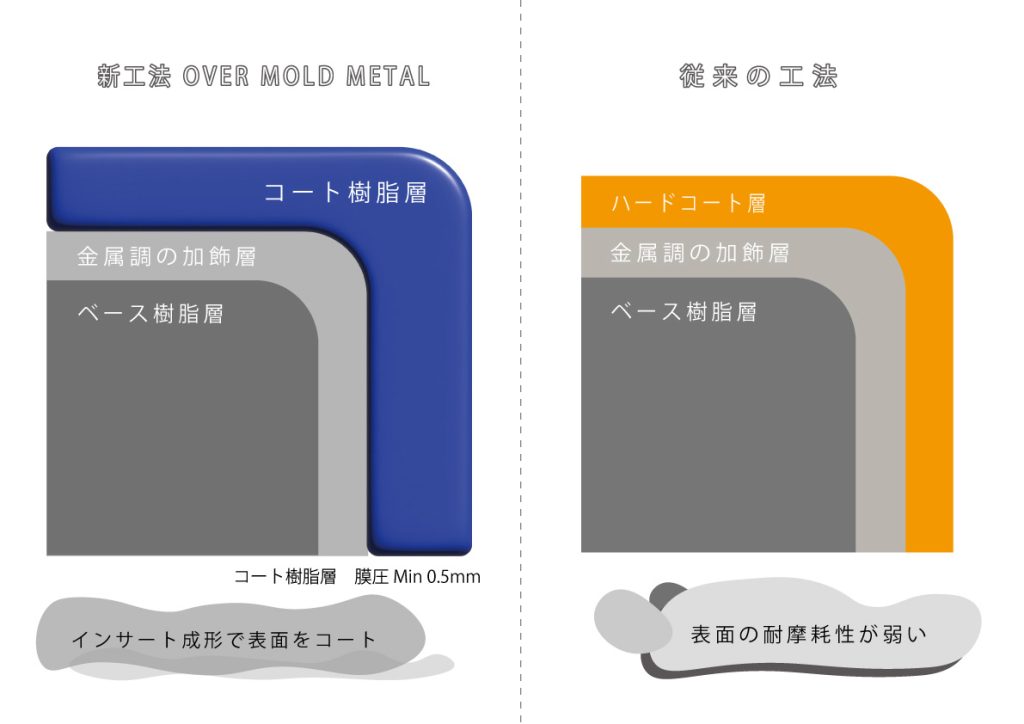

Proprietary technology Deposition that does not peel off

In order to make resin parts look metallic, a thin metal film is formed on the resin surface using a decorative technique called "vapor deposition." In general, vapor-deposited parts are coated with a thin resin film to protect the metal film. Since it is a thin resin film, the film wears and the metal film peels off during use, resulting in the appearance of the resin skin.

The non-peelable vapor deposition makes it possible to protect the parts with a thick resin layer by insert molding the parts after the vapor deposition, and has achieved a level of wear resistance compared to conventional paint coats. In order to maintain the vapor deposited layer during insert molding, advanced condition adjustment is required, which is our unique know-how. The shape of the product is also important, so please consult with us from the design stage.

Basic configuration

Examples of technology adoption

This technology has been adopted as a housing part for smartphones.

The corners of the casing are decorated using discontinuous vapor deposition to create a stylish design while not affecting antenna performance.

Besides that

Protection of watch metal bandsAs…

Automobile interior/exterior partsAs…

sportswear logo partsAs…

Apparel clothes, emblems, bag accessoriesAs…