rubber molding

・Using synthetic rubber compounding technology, we can develop rubber materials that meet customer needs.

・A wide range of rubber switches can be produced by combining conductive pills, gold contacts, conductive printing, etc.

・We have a wealth of experience in manufacturing rubber switches with click structures, and can respond from the design stage.

compression molding

Compression molding is a historical molding method in which rubber material is placed in a heated mold and poured into the mold under pressure to crosslink the rubber. The initial cost is often low because the mold structure is relatively simple, but as the molding method is based on the premise that a residue called burr will be produced, appropriate post-treatment is required.

We handle everything from design to manufacturing in-house for rubber molds.

We will propose the optimal configuration based on the product design, such as a general two-piece mold or a multiple-piece mold manufactured by inserting metal or resin.

| merit | Demerit |

| Initial cost may be relatively low | Post-processing such as burrs is essential |

| Unlike resin injection molding, there are no passageways for materials such as runners, so materials can be used without waste. | long cycle time |

| Not suitable for products with complex shapes |

rubber insert molding

Insert molding is a molding method in which resin, metal, or other parts that you want to integrate with rubber are inserted during molding to create an integral part. Depending on the material of the parts, appropriate pretreatment may be required to integrate them. We also develop unique technologies that leverage our experience and know-how in manufacturing various insert molded products. In recent years, we have succeeded in integrating silicone rubber and polypropylene resin, both of which are said to be difficult to bond.

Have you ever had problems like this when purchasing silicone parts and resin (or metal) parts separately?

- After purchase, assembly work (cost) is required.

・Position misalignment occurs during assembly.

- It is difficult to firmly assemble the parts.

· It is unclear whether the cause of the assembly failure is the insert part or the silicone rubber molding process.

- It is troublesome to place orders with multiple companies.

Advantages of integrally molding silicone parts with resin (or metal) parts

- No assembly work required after purchase.

- No assembly misalignment occurs.

- Firmly combines silicone and resin (metal).

-It is an integrated part, so there is no problem with assembly.

・We will mold it as a single piece.

Why does Sunarrow mold the resin parts it inserts in-house?

The important thing with one-piece molding is that the insert parts are in the correct condition.

- The material must be suitable for one-piece molding.

- The surface must be in a suitable condition.

- Appropriate pre-treatment has been carried out.

- The dimensions are appropriate.

We can manage these appropriately and use our accumulated know-how to perform insert molding.

In order to provide this, we need to mold it in-house.

Why Sunarrow excels at integral molding of silicone rubber and resin (or metal)

・Since establishing insert molding technology for silicone rubber and polycarbonate resin in 2003,

Because we have a wide variety of production experience.

- Because we can mold the integrally molded plastic parts in-house.

・When making parts into one unit, consideration should be given to the convenience of the assembly, the convenience of the molding die, and the convenience of the molding conditions.

This is because we can respond to your request by taking into consideration factors such as production efficiency and quality.

Achievements: Examples of materials integrally molded with silicone rubber

PP, PBT, PC, PA, TPU, PPS, PC/ABS, urethane film, stainless steel, aluminum, ceramics

*Even if the resin or metal is the same type, adhesion will vary depending on the manufacturer and grade.

PP resin integral molding example

Water bottle cap: Seamless stopper

The story behind the development of Zojirushi Corporation's "Seamless Sen"

"Seamless Sen" | See, this is Zojirushi.

| Problems? | Conventionally, silicone rubber packing was attached to PP resin parts, but When the end user removes the packing to wash it, they may forget to put it back on or get dirt caught in it. There have been cases where the contents have leaked out due to the device being twisted when attached. |

| Resolution | By integrally molding PP resin and silicone rubber, we have created a packing part that will not come off. |

| Technology Development | Integrated molding of PP (polypropylene) resin and silicone rubber PP resin has excellent chemical resistance, so it is used in automobiles, tableware, medical products, etc. Both PP resin and silicone rubber are poorly adhesive materials, and it is difficult to firmly integrate them. Using our technology, we have succeeded in molding PP resin and silicone rubber into a single piece without any gaps, even in complex shapes. By reducing the number of parts through one-piece molding, we were able to not only reduce assembly man-hours for the manufacturer, but also contribute to resolving problems for end users. |

Urethane resin integral molding Adoption example

Watch band: Tough band

Extracted from the website of Casio Computer Co., Ltd.

The band is made of flexible silicone material that fits comfortably on the wrist. The upper surface is protected with a urethane sheet to improve wear resistance. In addition, the surface of the urethane sheet that comes into contact with the silicone on the back side is coated with gold or silver vapor deposition, giving it a stylish look that harmonizes with the metal bezel.

10 years in the making! The development story of G-SHOCK's "Tough Silicone Band" | CASIO

| Problems? | "I want to make a resin band with a metal texture," and "I want to use silicone material for my G-SHOCK. Silicone bands are not strong enough or resistant to wear." |

| Resolution | A tough band is achieved by integrally molding decorated urethane resin and silicone rubber. |

Unique technology Silicone encapsulation of electronic components

This is a technology that integrally molds electronic components such as circuit boards and IC tags with silicone rubber.

The silicone material protects the inserted electronic components without degrading their performance. In addition to protecting the entire electronic component, it can also be molded to partially seal it.

Basic configuration

![]()

Product example

- IC Film x Silicone

Original technology covered silicone

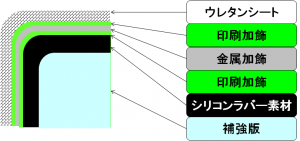

This technology achieves a soft feel, integrated structure, high durability, and freedom of design by molding a three-layer structure of reinforced plate + silicone thin film + decorative urethane sheet.

・Designs that cannot be made with paint are possible

・Can also be molded into 3D shapes

・High durability as the decorative surface is on the inside

・Can also follow the pattern of molded products

Basic configuration

Main environmental specifications

| item | Evaluation test | Judgment criteria | judgement |

|---|---|---|---|

| High temperature storage test | Leave at 85℃ for 240 hours | No change in appearance (discoloration, pinholes, blisters) |

○ |

| Low temperature storage test | -30℃×240 hours | No change in appearance (discoloration, pinholes, blisters) |

○ |

| temperature humidity cycle | +65℃~-10℃ 93±3%RH 10 cycles 240 hours |

No peeling of paint film or change in appearance (discoloration, pinholes, blisters) |

○ |

| Humidity test | 85℃90%RH 240 hours | No peeling of paint film or change in appearance (discoloration, pinholes, blisters) |

○ |

| hot water test | Soaked in 40℃ hot water for 240 hours | No peeling of paint film or change in appearance (discoloration, pinholes, blisters) |

○ |

| Weather resistance test | Xenon lamp irradiation for 240 hours | Significant discoloration or fading of the paint film, No crack marks |

○ |

design example

Unique technology silicone tray for microwave baking

A typical silicone tray can be used for cooking at temperatures of around 100℃ in a microwave oven, but by combining special materials with the silicone rubber developed by our company, we have created a tray that can be heated to temperatures of over 200℃ in a microwave oven. Developed. Even if you don't have a microwave oven, you can use this tray to cook bread and dumplings in the microwave. Since we can control the amount of heat generated by mixing the materials, we can develop trays for a variety of uses.

- Specially blended silicone x silicone

Unique technology Silicone high slip treatment

By applying this technology to silicone molded products, the surface becomes more slippery, giving it a smooth and slippery feel.

This technology can be expected to prevent sticking to silicone transport jigs and prevent foreign matter from adhering to silicone products themselves.

Unique technology Conductive silicone ink

It has conductive silicone ink that has the same performance as the conductive pill contacts used in silicone rubber switches. Conductive pill contacts can only handle fixed shapes such as cylinders, but by printing our conductive ink, we can handle contacts with complex shapes.