Sunarrow is putting particular effort into development activities.

NEEDS ∞ SEEDS

Our strength lies in our attitude of constant growth and never allowing ourselves to maintain the status quo.

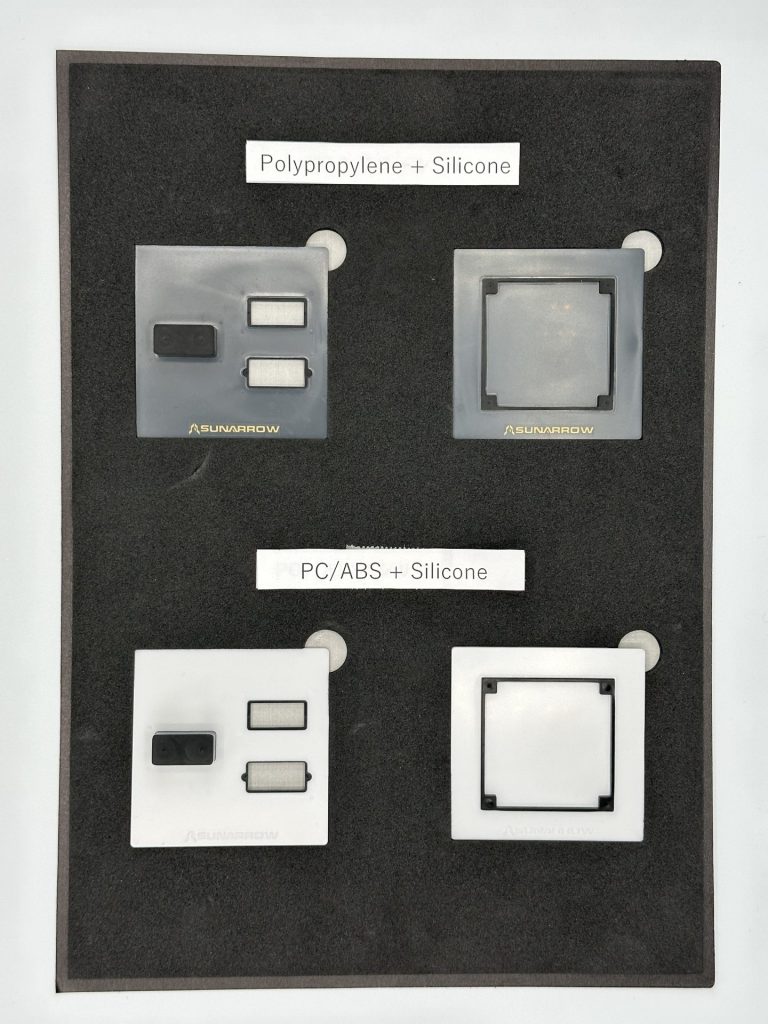

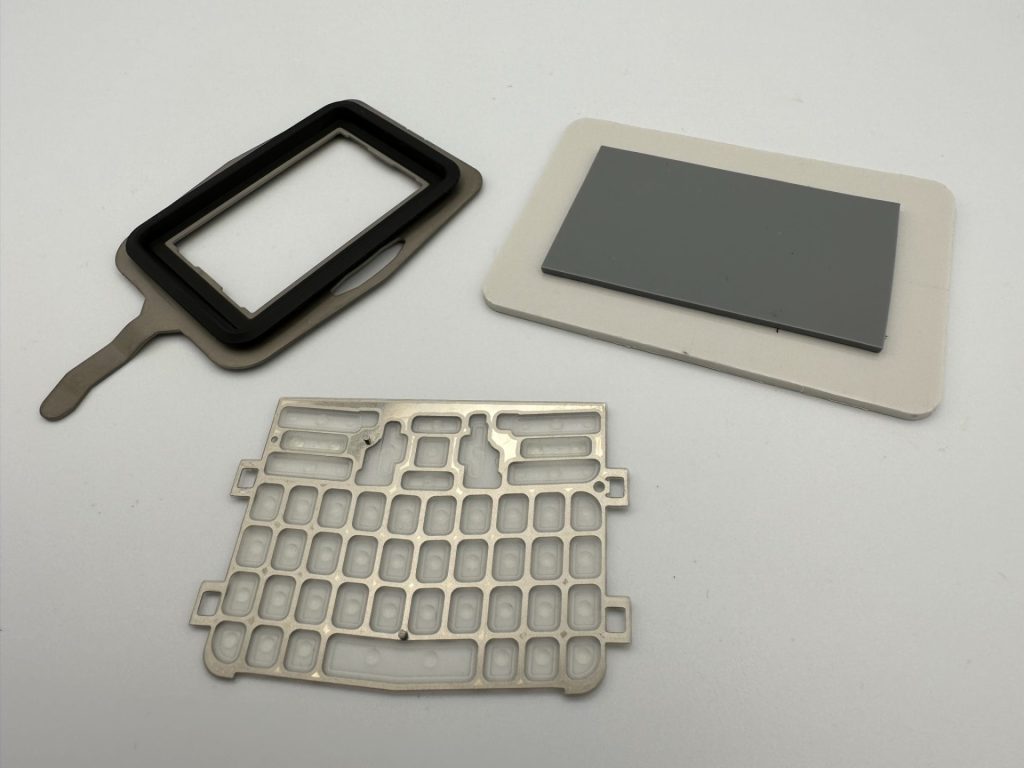

We want to decorate rubber...We want to make products that are integrally molded with resin and rubber...We want to pursue a high-class design...In order to respond to these customer needs, Sunarrow has established a department called the Product Planning Department. We are developing various technologies and applying them to mass production.

A characteristic of our needs-based development activities is that we work together with customers from the prototype stage to ask them, ``Can we do something like this?'' or ``Can we solve the problems they are currently facing?'' and thereby improve them with a view to mass production. I'm going to layer it up.

New needs and issues arise when technologies created from needs are applied to other products. These will never end and we will continue to work on them as new development themes for our company.

Our company actively engages in development activities through collaboration between industry, academia, and government. In the medical field, we have developed a pediatric surgical simulator in collaboration with the Nagoya University Graduate School of Medicine's Department of Pediatric Surgery. It is possible to provide surgical training for cases such as esophageal atresia, duodenal atresia, and congenital biliary dilatation, and off-the-job training seminars are held to provide practical training using this simulator.

Niigata University School of MedicineThe endoscope hood, which was developed in collaboration with the company, is a product that can be attached to the tip of an endoscope to grasp and collect tissues or foreign objects during endoscopic treatment or examinations. The rubber part that looks like a flower petal protects it from foreign objects, etc.organsIt is possible to collect foreign objects without damaging them.

A skin patch developed in collaboration with the Tohoku University Graduate School of Engineering is equipped with an enzyme-based biopower generation mechanism. It has the function of promoting the penetration of drugs, etc. into the skin. Not only that, it is also possible to install a porous microneedle array (PMNA) as a customized menu. The product is expected to have applications not only in fields such as medicine and health, but also in fields such as agriculture and livestock farming, and is continually being improved.

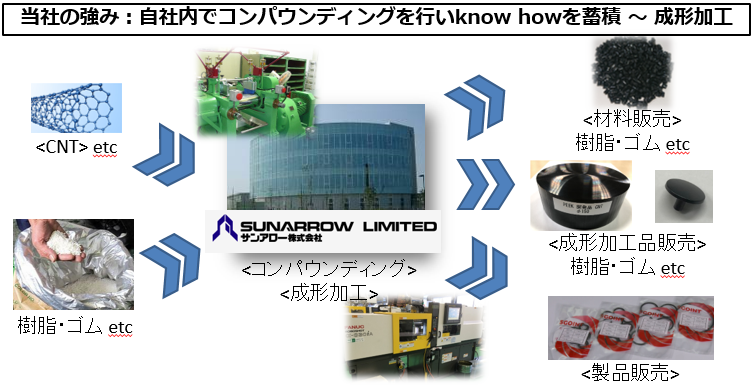

In collaboration with the National Institute of Advanced Industrial Science and Technology (AIST) and Zeon Corporation, we have cultivated know-how regarding the compounding and dispersion of various nanomaterials, including carbon nanotubes, into resins, rubbers, and solvents. Ta. By combining this know-how with the advanced molding technology that we already possess, we are creating new products with unlimited possibilities.

As a product, "SGOINT" is an O-ring that achieves high strength and high conductivity. The material is "SARPLUS", an ESD countermeasure material that is a composite of PEEK resin and CNT. In recent years, we have developed "Sunzaro", an amorphous material using silica particles and inorganic fibers, as an in-house product.

We carry out our daily activities with the mission of not only developing seeds but also enriching the lives of our customers by creating needs for products.