UV molding

- Molding technology that uses ultraviolet curable resin, suitable for thin molded products.

・Can be used to create products with low environmental impact.

・Proprietary technology 3D texture that can add design quality.

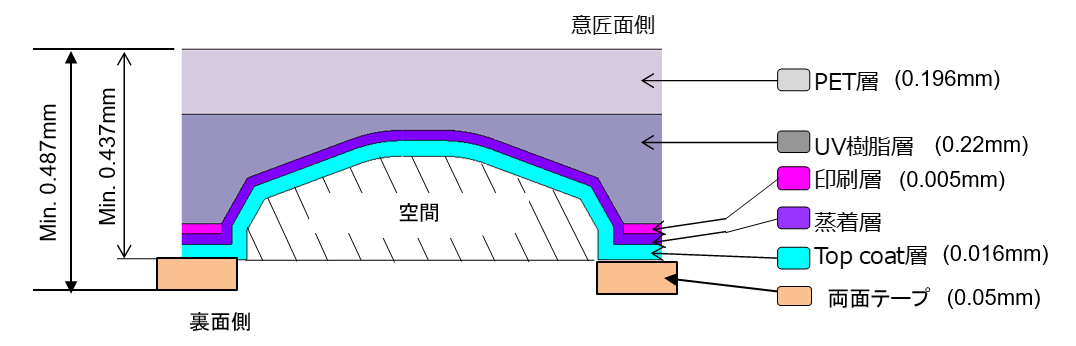

UV molding_configuration diagram

Sunarrow has molding technology that uses ultraviolet curable resin (hereinafter referred to as UV resin). A feature of UV resin is that it requires less energy for molding than injection molding of thermoplastic resin. Also,Suitable for thin products that cannot be made by injection molding..

Since the UV resin follows the detailed design of the mold, it is also good at creating delicate expressions such as hairline patterns and spin patterns. Since it is possible to have multiple designs in the same mold, it can be applied to a variety of products.

This technology has been used in products such as cell phone key sheets and remote controls, and is one of Sunarrow's strengths.

design example

- hairline pattern

- diamond pattern

- leather grain pattern

- carbon pattern

- spin pattern

- dot pattern

Unique technology 3D texture

We are developing 3D textures as a unique technology using UV molding technology.

3D texture is a technology that can express a visual three-dimensional effect to logos and letters inside ultra-thin sheets. Products using this technology are called 3D Deco sheets. 3D Deco sheet allows for flexible color variations, which not only improves the design, but also because decorations such as logos and letters are applied to the back of the sheet, so there is no need to worry about them peeling off.

Basic configuration

Cross-sectional view of the decorative part By increasing the thickness of the UV resin layer in the diagram above, it is possible to create a more visual three-dimensional effect.

By increasing the thickness of the UV resin layer in the diagram above, it is possible to create a more visual three-dimensional effect.

Main environmental specifications

| item | Evaluation test | Judgment criteria | judgement |

| high temperature test | Leave at 85℃ for 96 hours | No change in appearance (wrinkles, cracks, swelling, peeling) | 〇 |

| Low temperature test | -40℃×96 hours | No change in appearance (wrinkles, cracks, swelling, peeling) | 〇 |

| High temperature and high humidity test | 78℃ 85%RH x 96 hours | No change in appearance (wrinkles, cracks, swelling, peeling) | 〇 |

| thermal shock test | 85℃~-40℃ 30 minutes each x 500 cycles | No change in appearance (wrinkles, cracks, swelling, peeling) | 〇 |

| chemical resistance | Wipe off after applying chemicals and leave for 7 hours (gasoline/acid/alkali/hair conditioner/hand cream) | No change in appearance (wrinkles, cracks, swelling, peeling) | 〇 |

| Lightfastness | Apply light (500W/m2±100W/m2 wavelength range 300nm to 700nm) in accordance with JIS B7751 for 200 hours to check appearance. | No change in appearance (wrinkles, cracks, swelling, peeling) | 〇 |

Color variation example

FAQ

Q. Is it possible to paste 3D Decosheet on a distorted surface?

A. 3D Decosheet is designed to absorb some distortion. Please contact us for details.

Q. Will the antenna performance of the decorative surface be affected?

A. The decorative surface is decorated using indium discontinuous vapor deposition, so it does not affect antenna performance.

Q. Where is this product manufactured?

A. The development stage and prototype production are at the Sunarrow Niigata factory. Mass production will be handled at our Thai factory.