Decoration

・Decoration is a technology that adds value such as design and functionality to things, and includes "painting," "metal deposition," and "printing."

・Sunarrow has decorating technology not only for resin parts, but also for rubber and film parts.

Vapor deposition/sputtering

Vapor deposition is a process in which metal raw materials are heated in a vacuum and evaporated, so that the vaporized raw materials adhere to parts and form metal films.

What is sputtering? Sputtering is called the "sputtering method." By passing electricity through argon gas and colliding ionized gas particles with metal raw materials, atoms and molecules are ejected from the raw materials.board partsThis is a film formation method that forms a metal film by adhering to the surface.

It is said to be ``dry plating'', which replaces the old ``plating'' technology, and is a relatively new technology that reduces the environmental impact during manufacturing. Both are often used to give the appearance of high-grade metal parts by forming a metal film on the surface of resin parts.

We have resistance heating vacuum evaporation equipment and in-house sputtering equipment. Discontinuous deposition is also possible, and radio wave transmission specifications and half mirror specifications are also available.

Painting

This is a decoration technique that sprays paint onto the surface of resin, etc. In addition to general painting, we also perform relatively difficult painting such as high-brightness metallic painting and pearl painting that create a luxurious look. In addition, a hard coat treatment is applied in the final process to protect the painted surface from wear.

Even though it is simply called painting, there are compatibility depending on the type of resin and paint that is being sprayed. If the materials are not combined properly, problems such as uneven coloring and peeling may occur. We have a lot of experience and knowledge about paints, so please feel free to contact us. In addition, we can also paint not only resin but also silicone rubber parts.

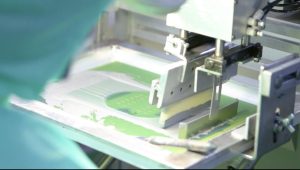

printing

This is a technology that prints ink onto target parts in any desired shape. Our company can mainly handle screen printing and PAD printing.We use "screen printing" to print on flat shapes, and "PAD printing" to print on uneven parts. We have a track record of printing on a variety of base materials such as resin parts, silicone rubber parts, glass parts, and film parts. Techniques for selecting the appropriate ink for the base material are also required.

In addition, we have developed an in-house conductivesiliconeBy printing ink onto a product, it is possible to make the applied area conductive. What sets us apart from other companies is our ability to respond to a variety of printing technologies.

Hot Stamp

This is a decoration technology that uses heat to transfer metal foil onto the back side of resin parts to give them a metallic feel. By hot-stamping the back of a transparent plastic key button, you can obtain a luxurious decoration with an excellent metallic luster, and by combining it with printing before and after transferring the metal foil, you can create a color mirror surface, light transmittance, and luminosity. It can have light blocking properties. This technology is often used in the buttons of mobile phones.

laser processing

By combining painting and printing techniques, we decorate parts with letters and patterns. By painting, it becomes possible to decorate parts such as letters with backlight using colored parts. Available with resin and rubber parts. Since we have special equipment, we can also perform laser cutting on white paint.

- Before processing

- After processing